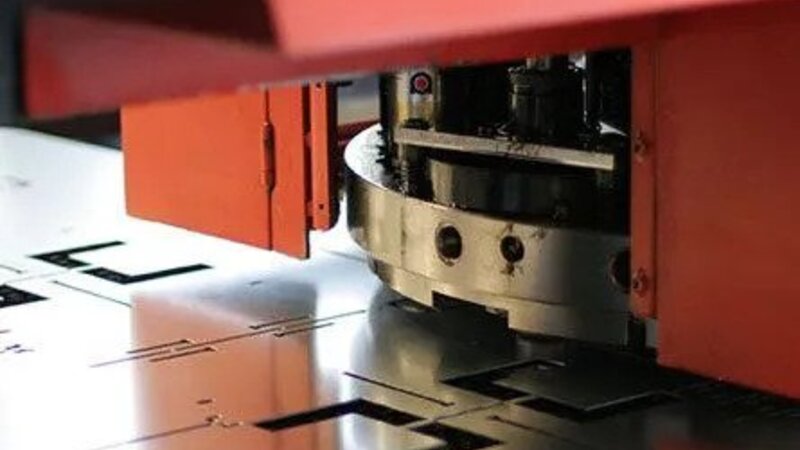

A wire EDM machine shop uses a process called Electrical Discharge Machining in which they remove metal in a controlled way by melting it rather than cutting it. This method vaporizes materials by electric spark erosion, and it leaves very little debris behind while delivering very accurate results. Machinists can process both large and small pieces through controlled metal removal.

What to Expect

When choosing the best wire EDM machine shop, it is important to choose one that is a leading custom metal fabricator in North America. The best shops have years of experience, and they can handle projects of all sizes. In addition, they can fulfill projects that have a scope, specifications, and a timeline that other fabricators say isn’t possible. Expect them to be ITAR registered and both ISO and NIST compliant. They offer custom gear cutting, spline cutting, die and mold fabrication, custom prototyping, and more. This type of machine can fulfill larger projects with a capacity of up to 6,600 pounds.

Benefits of Wire EDM Machining

There are many benefits to working with a wire EDM machine shop. Not only can they fulfill larger projects, but they can achieve tighter tolerances. In fact, the best shops can achieve tolerances as tight as 0.0001,” which is smaller than a human hair. This process places no stress or force on the workpiece as it removes the material, and the parts are processed while submerged in deionized water. This process can be used to machine brittle materials, as well as hard, conductive materials.