Extruded aluminum plays a crucial role in most industries. It is the major component found in bikes, cars, subway trains, boats, and airplanes. Aluminum extrusions are not only used on the exteriors of vehicles and planes, but also in the internal framework. The fasteners that hold the entire structure together are also built using aluminum.

There are millions of things that you don’t know that are made with aluminum extrusions. From the display units in supermarkets to the grooved bleachers in sports fields and stadiums, all are made using extruded aluminum.

What is Extrusion?

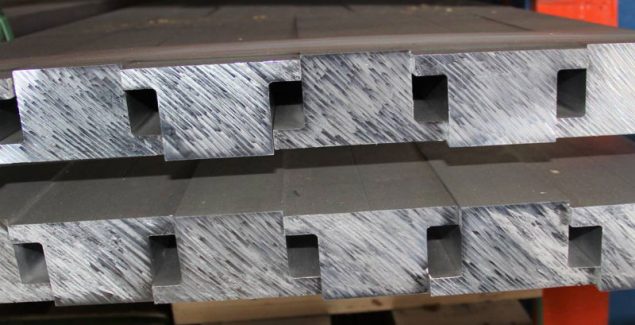

This is the process of shaping a variety of molten plastics and metals. The materials are forced into different shape designs under extreme pressure. The process is very flexible. Because of this, there are several ways to perform extrusion, including either continuous or semi-continuous and hot or cold.

Other Applications of Aluminum Extrusions

Transport Industry

In this industry, the strength-to-weight ratio is essential. Top Aluminum Extrusion Companies make extrusions ideal for transmission housings, engine blocks, roof rails, panels, and chassis of boats, cars, railway, and trucks and subways cars. The demand for extrusion aluminum in this industry is growing.

Heat Conductivity

Aluminum conducts heat and electricity efficiently. This metal is commonly found in condenser tubes, air conditioners, pharmaceutical thawing units, and nuclear reactors. It is also found in the cooling devices of electronics, cooling apparatus of computers, and visual/audio systems.

Aluminum Extrusion Companies note that the most significant attributes of aluminum are its naturally corrosion and rust-resistant. This is because it has a naturally occurring film of aluminum oxide that binds to its surface.