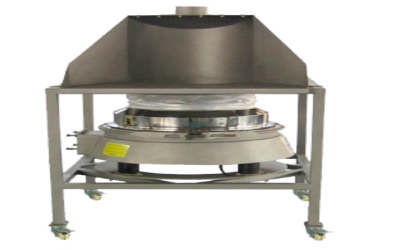

This technology can be manual or automated, with the latter being predominant in modern applications due to its efficiency and reliability. An industrial sieve is a crucial device used extensively in various manufacturing and processing sectors to separate particles and materials based on size. The basic mechanism involves a screen or mesh that filters out undesired materials, allowing only particles of a specific size to pass through.

Applications Across Industries

Sieving plays a pivotal role in the food and beverage industry, ensuring that only particles of the desired size are included in the final product, thereby guaranteeing purity and quality. In the pharmaceutical sector, sieves are essential for the consistency of powdered ingredients, which directly affects the efficacy of medications. Similarly, in mining and construction, sieving is used to sort materials and filter out debris, contributing significantly to the quality of the building materials produced.

Benefits of Employing Industrial Sieves

The strategic use of advanced separation techniques leads to improved product quality by enabling precise sorting processes. This precision not only enhances the efficiency and speed of production lines, resulting in higher throughput but also reduces operational costs by minimizing waste and optimizing the use of raw materials.

Technological Advancements in Industrial Sieve Design

Innovations Enhancing Sieve Performance

Recent developments include the introduction of multi-layered sieve designs that facilitate the simultaneous sorting of various particle sizes, significantly boosting productivity. Additionally, the integration of IoT sensors in sieves helps monitor performance in real time and predict maintenance needs, thereby preventing unexpected downtimes.

Material and Design Optimization

Materials such as stainless steel and advanced synthetics are commonly used in sieve construction, offering durability and compliance with food safety standards. Modern sieves also feature ergonomic designs that simplify handling and cleaning, further enhancing operational efficiency.

Environmental Impact and Energy Efficiency

Contemporary filtration systems are designed to be energy-efficient, playing a crucial role in reducing the carbon footprint of operations. The recyclability of the materials used and the overall design of these systems also reflect the industry’s shift towards more sustainable practices.

Best Practices for Maximizing Sieve Efficiency in Industrial Settings

Routine Maintenance and Upkeep

Maintaining sieves involves regular cleaning and the timely replacement of worn parts. Establishing a maintenance schedule is crucial for ensuring their longevity and consistent performance.

Training and Operational Best Practices

Proper training in operating sieving equipment is essential for safety and efficiency. Operators must be skilled in configuring settings to suit the specific requirements of various materials and achieve the desired results.

Evaluating and Choosing the Right Sieve

When selecting an industrial sieve, consider the specific needs of your industry, the types of materials processed, and your production goals. Consulting with manufacturers for customizable solutions can greatly enhance the suitability and efficiency of equipment. By understanding the significance of screening technologies, staying updated with technological advancements, and adhering to best practices in maintenance and operation, industries can significantly boost production efficiency. This strategic approach not only optimizes resource use but also supports sustainable industrial practices.