Flexible heaters use a product called Kapton to create thin heating elements. Kapton is a polyimide film that’s amber in color and clear. A heater’s design is like those made with etched foil silicone. A bottom layer of Kapton is etched to create a circuit pattern, which is mated with an upper layer. This laminating process creates a thin and flexible design that can operate in the -300°F to 392°F range and demonstrate exceptional non-conductive dielectric properties.

Attributes

A Kapton film heater typically operates between 1V and 240V and can be fashioned in any wattage, size or shape necessary. Outstanding characteristics include low weight, unique dimensional stability, excellent tear strength and tensile strength. They’re low-thermal-mass devices that heat up and cool down quickly. Additional attributes include:

- Semitransparency

- High flexibility

- Thermal stability

- Even heat distribution

- Lightweight construction

Industry Applications

A Kapton film heater’s capacity for even heating and its lightweight design make it a versatile device for a variety of applications:

- Aircraft Industry

- Semiconductors

- Aerospace

- Food Processing

- Medical Industries

- Vacuum Chambers

- Satellite Construction

- Sterilizers, incubators and snow melting

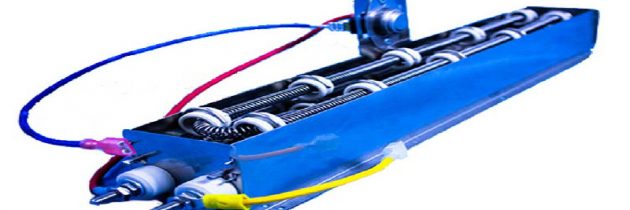

An Industry-Experienced Wire and Element Processor

We’ve built a decades-long reputation as a foremost processor and producer for flexible Kapton film heaters as well as open-coil, printed, mica and moisture-resistant heaters and wire harnesses. We’ve provided creative engineering solutions with stringent manufacturing standards and short lead times, helping industrial and commercial customers minimize inventory and reduce overall costs and prices.