People looking for aluminum for sale do not just want the lowest prices. They want quality metal guaranteed by the distributor. A 100% aluminum distributor assures you of the excellence in their product and provides attention to your needs, whether it is plate bar, or extrusions.

Custom Aluminum Extrusions

The advantages of custom aluminum extrusions include:

- Eliminating machining times

- Reduced wear and tear on tools

- A faster production time that saves you money

- Increased productivity

- More environmentally friendly

- Increased profits for you

What is Extrusion?

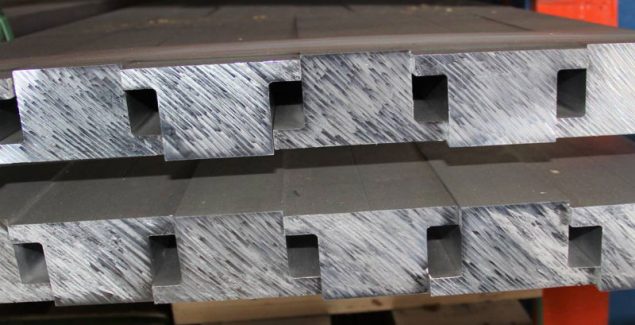

Extrusion is the process of forming metal by forcing a cylindrical billet, or bar, through a die of the required design to form the desired cut or shape. Numerous shapes that can be accomplished by extrusion, such as:

- press and snap

- sliding fits

- tongue and grove

- self-tapping screw holes

- flanges

- and much more

Aluminum Casting

Casting is the method most widely used to form aluminum. This is a relatively simple and inexpensive process for shaping aluminum into many different forms for a multitude of purposes.

The process of casting can employ either die casting or mold casting. In die casting, the molten aluminum is forced into a steel die, or specialized tool used to cut or shape the aluminum with a press. This is different from the extrusion method.

Whereas aluminum extrusions are limited by the size of the billet and the capacity of the press, castings can produce quite large items.

Whether the aluminum for sale you seek requires extrusion, casting, or cutting, choose this premier metal distributor to meet your needs.