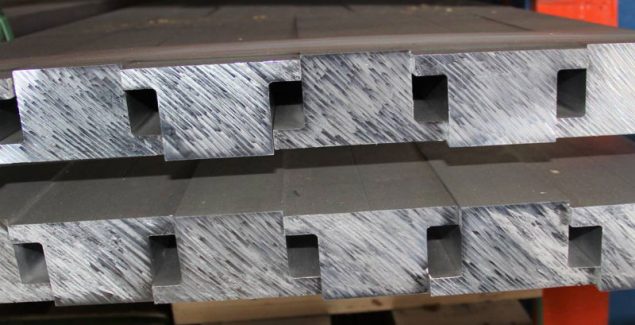

Using custom aluminum extrusions is essential in many different industries. Standard extrusion shapes may not offer the specific structure or design required. The use of custom extrusions may also save time in trying to shape and process standard extrusions to work as a component in a design, plus then can help to cut the costs of production over time.

Regardless of why you choose a custom extrusion, finding the best aluminum extruders is always going to be an essential consideration. A simple option is to find an aluminum service center and have them handle the custom extruder selection and management. This is a great solution that will help you to avoid three very common mistakes that design teams and even experienced project managers make during this process.

Not Verifying Experience

Not all aluminum extruders are a good match for every type of extrusion processing requirement. Some may have very large volume minimum orders while others may be ideal for prototype development but not geared for high volume production.

Some other extruders may be relatively new to the market. While there is nothing wrong with working with a new company, they will be an unknown factor. This makes it riskier than working with an established extruder with a proven track record.

Lack of Networking with Quality Extruders

By going to individual aluminum extruders you may be missing out on the opportunity to use an already existing die or a die that just needs minor modifications to fit your requirement needs.

An aluminum supply center with a good network of extruders will be able to track down just the material you require. This is because they have an ongoing working relationship with the top mills and extruders, a combination that can end up saving you both time and money.

Missing Additional Services

When working with a top aluminum supply center, you will also have the option to use their additional services for your order. This can be a very big cost and time-saving factor to consider.

Precision cutting of the custom extrusion to the exact specifications you need can save you money in two different ways. First, you will only be paying shipping on the aluminum you are using without any extra of the waste material. Second, with precision cutting every cut is perfect every time, which will certainly not be the case with in-house cutting processes.