The heavy machinery used in many Dallas industries needs to be expertly re-calibrated at regular intervals. Today, most alignment is done using laser equipment, which few company employees are trained to do. Most businesses outsource Machine Laser in Dallas to specialists. These highly skilled technicians use lasers to ensure the machinery is operating precisely and efficiently. Their work allows clients to consistently produce quality results and maintain productivity levels.

What Is Laser Alignment?

Technicians use machine laser in Dallas to make sure equipment is operating at peak efficiency. Industrial machinery needs to maintain precise tolerances to produce quality results. However, over time, or when equipment has been moved, these tolerances can change. At one time specialists used hand-strung wire that was placed at intervals along points being measured. The process was tedious and time consuming. Laser technology is much quicker and more accurate. It can be used to diagnose and re-align machines.

Laser Alignment Benefits Dozens of Industries

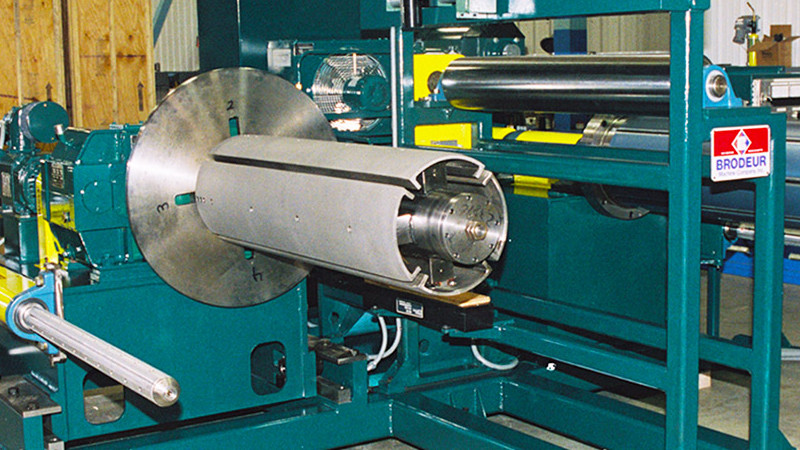

Virtually any industry that relies on delicately calibrated machinery uses laser alignment. For example, technicians routinely align machinery for the aerospace, printing, tool manufacturing, power, and auto industries. Technicians work with injection mold equipment, lathes, and other machinery. Some of the applications they offer include:

1. Spindle Alignment

2. Machine Geometry

3. Bore Alignment

4. Roll Alignment

5. Coupling Alignment

Alignment Dramatically Impacts Business Operations

Both large and small businesses use the “Contact Us” sections at sites like http://laserprecision.net to arrange services that increase productivity. Alignment technicians are very efficient, and calibration is often completed in a single day. Professional adjustments help reduce maintenance-related downtime. They can also minimize work space setup, since less shimming is required before beginning operations. Expert calibration ensures that measurements and positioning are precise, which is critical in businesses like shipbuilding, aviation, and automotive manufacturing. Laser alignment helps clients reduce scrap parts and increase tool life. In addition, technicians can install machine tools and provide diagnostic services.

Industries using delicately calibrated machinery depend on laser alignment specialists for routine calibration due to usage and after equipment moves. Laser experts have the tools and training to evaluate, diagnose, and re-calibrate virtually any type of machinery. Their efforts help clients increase productivity, reduce downtime and maximize profits.