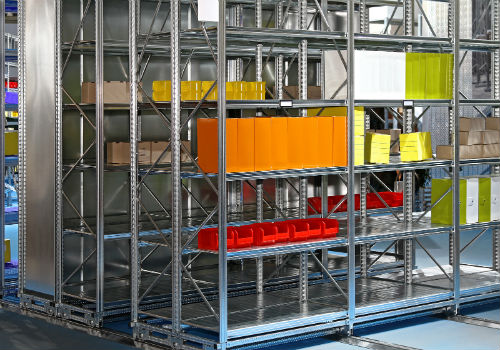

When working with an industrial shelving system, you will want to find the most efficient process and design to support your company. When an effective system is in place, you will notice there is more flexibility, fewer safety concerns, and a significant increase in efficiency.

There are many ways to organize your warehouse. Some of these methods include labeling areas and tools, maximizing shelf space to fit stock of various sizes, designating specific products to a commonly known space, making searches for products more manageable by using color-coding, and researching and experimenting with many stacking methods.

Here are five strategies to get more done, whether you are using metal shelving, wired shelving, or pallet racking.

1. Various storage shelves

An essential aspect of increasing efficiency is to purchase several kinds of storage shelves. With each one, you can customize your warehouse, so there is no wasted space.

Options include boltless, steel, open, closed, and multilevel shelving.

- Boltless shelving is simple to install as it requires only a rubber mallet.

- Steel shelving offers you a way to reach your maximum payload capacity as it supports significant weight.

- Closed shelving, open shelving, and multilevel shelving provides protection and will allow your staff to access any products quickly.

Other aspects that can boost the efficiency of your warehouse and its safety are lengthy spans, easy assembly, and secure bracing.

For many companies, a full warehouse means more organization is needed, which can be accomplished with a variety of shelving.

2. Vertical storage

To maximize space in your warehouse, vertical storage is an excellent strategy.

When products are stored vertically, your company can utilize the height of your space and keep items from the warehouse floor that may block the aisles and lead to injuries.

3. Mezzanine (or platform) shelving

If you would like the floors of your warehouse to feature minimal shelving, installing mezzanine shelving is ideal. This design places all storage on the second floor of your facility.

Mezzanine flooring is also helpful to prepare packaging and shipping products. The extra space provided leaves space to operate heavier products on the main floor safely.

4. Specific sizes

Sorting your inventory by size can provide a tremendous boost in efficiency. For many companies, a lot of space is wasted when larger items will not fit in smaller spaces. Purchasing shelving that is size specific will increase organization, access, and overall efficiency.

To increase productivity, placing often-requested products near the dock and central shipping office will allow them to be easily loaded, stocked, and located.

5. Shelving with drawers

Sorting your inventory into industrial drawers can provide an enormous boost in efficiency. Many of these systems offer 200 to 400-pound capacity drawers for equipment. These can be labeled and provide excellent space for frequently used items.

Why your warehouse design is important?

Reorganizing your warehouse may take some time, but the increase in organization will be well worth the effort. When you have implemented more efficient stacking methods and trained your staff on ways to upkeep your storage facilities, you will see many advantages.

Reduced efficiency can cost your company tens of thousands of dollars, put a strain on your employees, delay your receiving and shipping processes, and lead to customer complaints.

Discovering the best shelving designs and layouts can lead to faster shipping, receiving, and handling times and a safer work environment. Often, warehouses may not adequately plan how to use their space. This practice can lead to a significant amount of wasted space, money, time, and effort.

When you design your storage facility before moving your stock in and gather the right tools (such as shelves that only hold items of a specific size), you can maximize the efficiency of your operations.

Conclusion

To increase the efficiency of your warehouse, consider a wealth of shelving options, vertical storage, mezzanine shelving, tailoring your spaces to the various sizes of your products, and gathering shelving that has built-in drawers.